Guide to Choosing a Micromanipulator

Questions and Answers about Micromanipulation

If your question did not get answered shoot us an emailIntroduction

A Micromanipulator is a device which can be used to scale down the movement of the human hand, particularly under a microscope, and deliver a high level of precision movement. Possible human interfaces include knobs, joysticks, buttons, and computer interfaces as well. Micromanipulators reduce the scale of movement from your hand on the input controls to a holder for micro-tools at the business end - to hold, inject, cut or otherwise manipulate a specimen.

Types and Specifications

The kinds of micro-manipulators

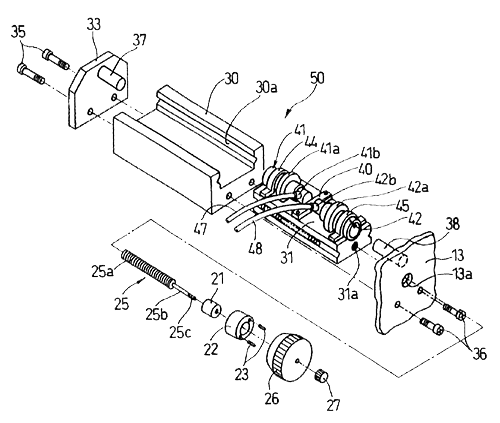

Reducing the movement can be achieved by using mechanical gears, levers, hydraulic (oil or water) pistons, electric motors, piezoelectric drives, or a combination of these methods. They can be arranged for different movement axes and different ranges of movement allowing coarse or fine movement to position something.

The movement axes

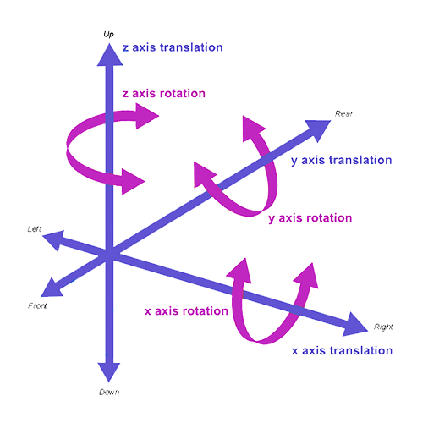

A Micromanipulator can have one or several axes of movement, generally described as X, Y, and Z, translating into horizontal (right / left), and (backward / forward) and vertical (up / dowm) movements.

Some units have an additional axis referred to as ”T” which allows you to move in and out in the axis of the tool itself. A few micromanipulators and nanomanipulators are designed for movement in polar coordinates via the rotational axes phi, theta, ro, and r... the radius.

The movement ranges

Fine movement micromanipulators permit operation in the nanometer (nm) to micrometer (µm) ranges; whereas, a coarse manipulator's movement is typically graduated in millimeters (mm). A full rotation of a coarse knob might move 18mm, whereas a full rotation of a fine knob might shift the tool 100 µm (100 microns).

Choosing a Micromanipulator

It is a jungle out there ...

There are many different types to chose from so it takes some research to determine the best choice. We are hopeful that our guide to find the best Micromanipulator for your application will help you and save some time and money.

The precision and type of interface that your applications require will influence the choice.

Which kind of movement (direction and range) do I want?

It will depend on your experiments!

Is it to hold and move a needle holder to inject a certain volume or is it to move materials around? Do you need to move it very far or on a relatively small scale? Do you need to move something crudely (coarse movement) or in very small, precise increments (fine movement)? Are the samples stationary (i.e. a neuron for patch clamp) or are can they move (i.e. cells in suspension, Drosophila and C.elegans)?

If you have a fine-movement micromanipulator, you will probably want to add a coarse-movement micromanipulator to position the microtools close to the target more quickly, and THEN fine-tune the positioning with the fine-movement micromanipulator.

Do you only want to position the tool and then move the sample toward the microtool? You don't need an expensive micromanipulator to do that! Check out the GlideStage®, which moves smoothly on a layer of grease and can be moved in an easy, intuitive manner.

M-3333

MN-151

MWS-31

MM3A-LS

Manual / Motorized?

The answer is dependent upon your applications as well as your budget. Also, personal preferences play an important role in the selection process.

Manual:

Micromanipulators can have different control mechanisms, each with a respective set of pros and cons. With knobs, there are individual controls which correspond to fine and coarse movement. This mechanism helps ensure precision in experiments because once you reach the desired location, the knob will remain in position, insuring stability.

The advantage of a joystick mechanism is that it mimics your hand movement, replicating the velocity and acceleration of your hand. A joystick mechanism is more effective in microinjection experiments, while knobs are better for patch-clamping.

With mechnical micromanipulators, the end-user touches knobs that are part of the micromanipulator, while with hydraulic and electrical type micromanipulators, the end-user operates the micromanipulator with a remote control so that there is virtually no chance of inducing vibration or creating torque.

Vibrational movements of the hand and frictional resistance have much lower impact with a hydraulic micromanipulator, but on the other hand, hydraulic units may need maintenance and the fluids in the manipulator are subject to thermal expansion.

Motorized:

The motorized micromanipulator allows high precision movement on a variety of axes, ensuring consistency and reproducibilty, and can also be remotely controlled, but most are designed to start and stop abruptly.

The Usual Suspects

In the following table, we will present the most popular and highest-reviewed micromanipulators for each respective application.

We have "borrowed" a matrix from Tritech Research, Inc. which we have found to be quite useful in finding the best micromanipulation tool.

| Feature | Direct Drive | Hydraulic Drive | Motor Drive |

|---|---|---|---|

| Popular | X | X | X |

| Coarse | X | X | X |

| Fine | X | X | X |

| Lightweight | X | X | n/a |

| Miniature | X | n/a | n/s |

| Ultre Precise | X | n/a | X |

| Extra Sturdy | X | n/a | n/a |

| Joystick | X | X | X |

| Rotating | X | X | n/a |

| Multi Electrode | X | X | n/a |

| Electrophysiology | X | X | X |

| Low Cost | X | n/a | n/a |